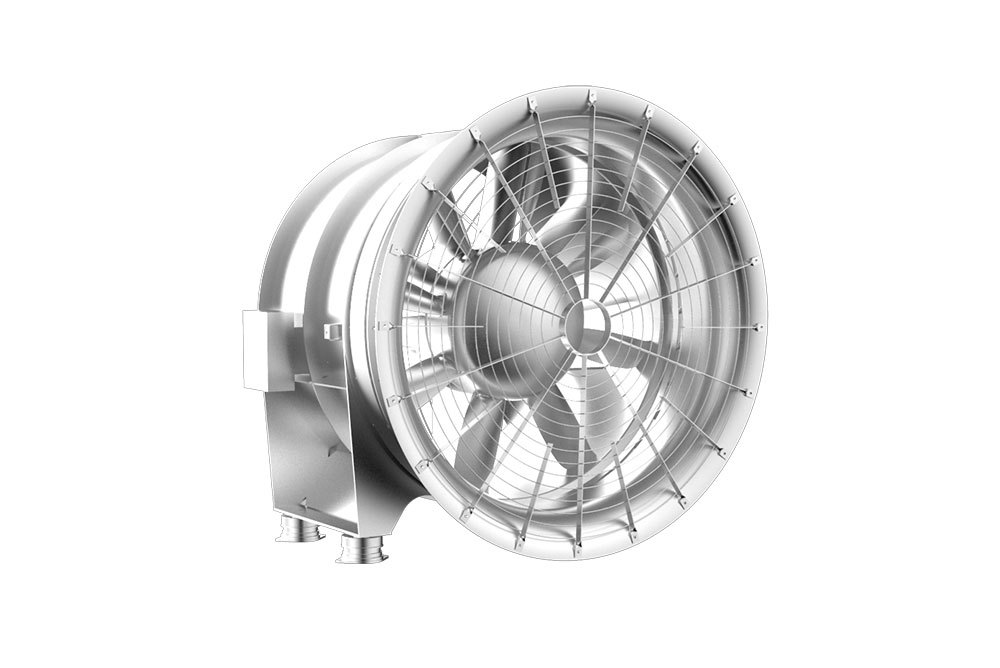

SDS series reversible jet fan

Product Introduction:

1. The impeller is manufactured using aluminum die-casting technology (blades can be manufactured using aluminum forging technology). The blades are symmetrical airfoil-shaped, optimized through software analysis to minimize losses at the blade tip and root, featuring a wide high-efficiency zone. The aerodynamic performance parameters for forward and reverse rotation are essentially equal, reducing rotational and eddy current noise.

2. The impeller undergoes non-destructive testing and mechanical performance tests. The blades and hub are fastened with high-strength bolts, ensuring reliable quality and sufficient strength safety factor. Appropriate technical measures are adopted under high-temperature conditions to guarantee safe operation.

3. The blade angle is adjustable while stationary. If necessary, users can change the blade installation angle according to actual needs.

4. The length of the silencer is usually one to two times the diameter of the fan and is bolted to the fan body.

5. The fan rotation direction can be switched between forward and reverse. Through the control cabinet, the forward and reverse rotation can be switched within 60 seconds (from the rated forward speed to the rated reverse speed, or vice versa).

6. A control cabinet can be provided as needed. The control cabinet uses a PLC as the core controller and supports Modbus RTU, USS, and free port communication protocols to connect with BAS and achieve system group control functions.

7. An intelligent control module can be provided as needed. This module is based on the data analysis and management platform of the Internet of Things system and integrates multi-sensor data technology. It is configured with big data acquisition and remote transmission systems to remotely monitor the fan's operating status in real time. According to the fan expert model, the module performs intelligent diagnosis of the equipment's operating status, effectively providing early warnings to prevent the expansion of faults, reduce emergencies, and minimize the need for part replacements.

Product Parameters:

Air Volume: 7.9~52.3m3/s

Thrust: 232~1614N

Diameter: 630~1600mm

Product Applications:

Widely used in subways, tunnels, and construction projects. By forcing ventilation and exhaust, sufficient fresh air is introduced into the tunnel while simultaneously expelling harmful gases, maintaining good air quality.

Keywords:

Axial flow fan

Category:

- Product description

-

Product Introduction:

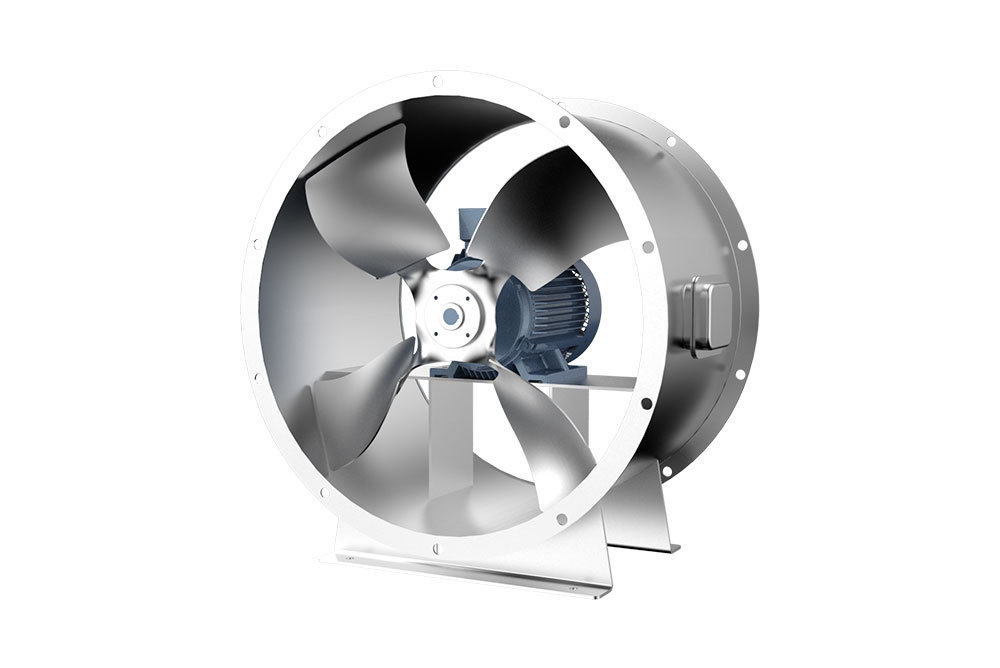

1. The impeller is manufactured using aluminum die-casting technology (blades can be manufactured using aluminum forging technology). The blades are symmetrical airfoil-shaped, optimized through software analysis to minimize losses at the blade tip and root, featuring a wide high-efficiency zone. The aerodynamic performance parameters for forward and reverse rotation are essentially equal, reducing rotational and eddy current noise.

2. The impeller undergoes non-destructive testing and mechanical performance tests. The blades and hub are fastened with high-strength bolts, ensuring reliable quality and sufficient strength safety factor. Appropriate technical measures are adopted under high-temperature conditions to guarantee safe operation.

3. The blade angle is adjustable while stationary. If necessary, users can change the blade installation angle according to actual needs.

4. The length of the silencer is usually one to two times the diameter of the fan and is bolted to the fan body.

5. The fan rotation direction can be switched between forward and reverse. Through the control cabinet, the forward and reverse rotation can be switched within 60 seconds (from the rated forward speed to the rated reverse speed, or vice versa).

6. A control cabinet can be provided as needed. The control cabinet uses a PLC as the core controller and supports Modbus RTU, USS, and free port communication protocols to connect with BAS and achieve system group control functions.

7. An intelligent control module can be provided as needed. This module is based on the data analysis and management platform of the Internet of Things system and integrates multi-sensor data technology. It is configured with big data acquisition and remote transmission systems to remotely monitor the fan's operating status in real time. According to the fan expert model, the module performs intelligent diagnosis of the equipment's operating status, effectively providing early warnings to prevent the expansion of faults, reduce emergencies, and minimize the need for part replacements.

Product Parameters:

Air Volume: 7.9~52.3m3/s

Thrust: 232~1614N

Diameter: 630~1600mm

Product Applications:

Widely used in subways, tunnels, and construction projects. By forcing ventilation and exhaust, sufficient fresh air is introduced into the tunnel while simultaneously expelling harmful gases, maintaining good air quality.

Related Products

Product

Nuclear grade products

Axial flow fan

-

DTF series metro tunnel axial flow fan

The blade is airfoil-shaped, characterized by high efficiency and a wide high-efficiency zone.

-

DTF(R) series reversible axial flow fan for metro tunnels

The impeller hub adopts internationally advanced aluminum die-casting technology or a special steel plate welding process.

-

T35-11 axial flow fan

The blades of the T35-11 axial flow fan adopt a combined design of bending and sweeping technology.

-

SF-NAF axial flow fan

HTF axial flow fire smoke exhaust fan, its basic form is axial flow structure

Cabinet fan

Centrifugal fan

Centrifugal fan

Air handling unit

Intelligent Operation and Maintenance System for Wind Power

Damper and silencer

Application Domain Comprehensive Page

Related Products

Product Inquiry

If you have any questions, please contact us and we will be happy to serve you!